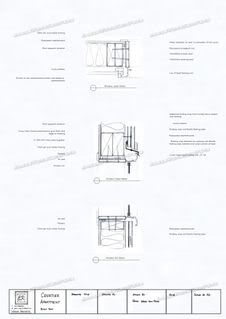

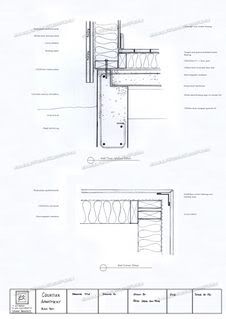

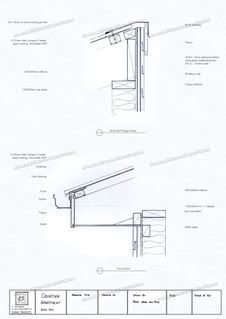

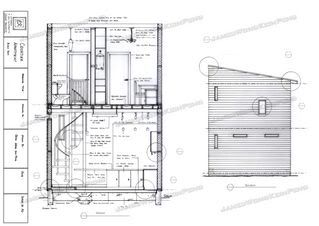

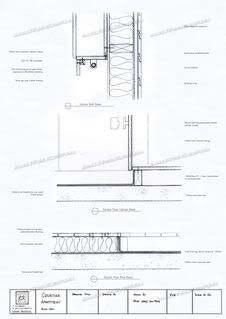

Hmm.. One of the toughest deadlines we were given (for the amount of work expected for the given time). This was part of a construction paper early on in the Year. It was intended to basically get us to familiarise with the building-code of New Zealand (NZ3604) and implement it into our designs. Things like keeping the joist or stud span consistent with the building code, which is affected by factors like loading, wind zones, building height, whether at 600 or 400 centres and so on.

Apologies for only including some of my detail technical drawings, as I don’t have digital copies of my plans, sections, elevations etc.

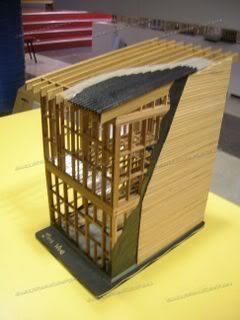

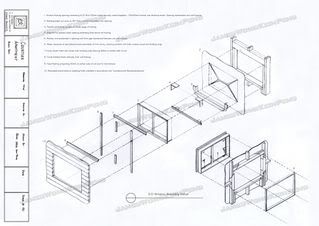

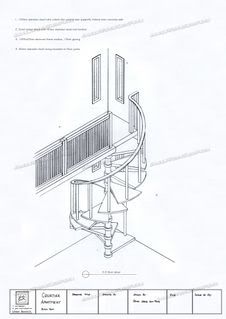

In essence this is a buildable apartment in New Zealand that should definitely get building consent. All our designs were to be placed side by side with each other so communicating with neighbouring designers was pretty vital. My model is to scale with every joist, beam, stud, lintel... .. to the right scale, dimension and length. Specifications of the materials used for cladding, interior finishes, insulation and joinery were also mentioned in the detail drawings.

Procedure: The hardest thing about it was that the model was that IT WAS ALL MADE OUT OF A PLANK OF CEDAR WOOD. I decided to use cedar as opposed to generic balsa as it had a much richer tone and finish to it. EVERY ELEMENT HAD TO BE PAINSTAKINGLY SAWN TO THE RIGHT DIMENSION. So that was one of the hardest parts of the project I recon. All in all it took about 80 plus hours at least.

![]()